In my quest to get back my lost X-axis travel from the original stock dust shoe, I have looked at far too many dust shoe write-ups and videos.

I found one that was innovative and decided to do a version for my Longmill. The video is here:

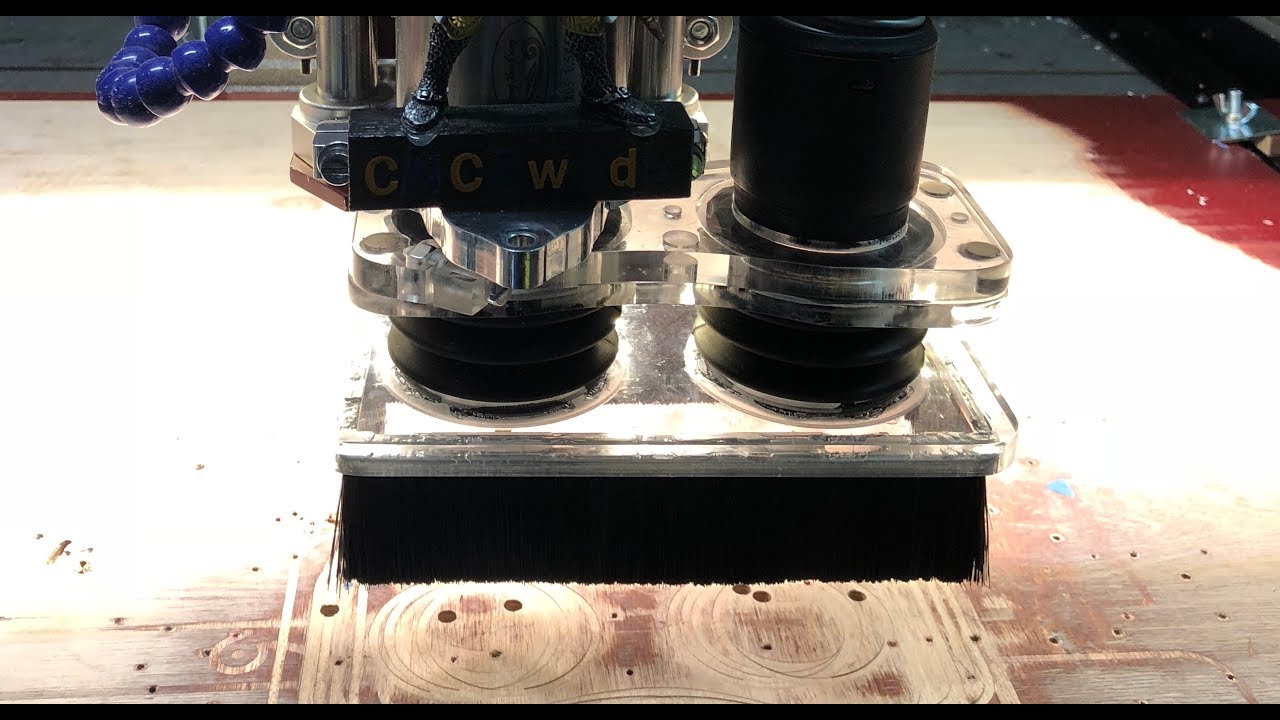

The show is unique in that it has an upper and lower portion and they are connected with a steering rack boot or other flexible ribber material and the distance between the lower foot/bristles and the upper piece can expand and contract (thus allowing the router to descend down in to cuts without jamming the shoe in to the stock).

I wasn’t able to find a suitable rubber boot that would accomodate the 65mm router body so I ended up using a $5 3" bathroom vent line I picked up at Home Depot: https://www.homedepot.ca/product/dundas-jafine-flexible-vinyl-ducting-3-inch-x-8-foot/1000142209

On my design I moved the vaccum connection out in front of the router and I attached to the sides of the router mount using the existing M8 holes. This hasn’t worked out especially well as they seem particularly susceptible to loosening to vibration so I’m rethinking that part. The lack of any accessory holes or railes on the ZX gantry is unfortunate, it would really help here.

I made my shoe out of 1/2" plywood as that was the thinnest thing I had that was of decent quality. I would like to use 3/8" baltic birch or even some plastics to reduce weight on my next attempt. The design needs refinement but works quite well otherwise.

The middle piece is connected to the top piece with some extremely strong ceramic magnets I picked up at Canadian Tire: (not exact but similar to these) https://www.canadiantire.ca/en/pdp/ook-magnetic-ceramic-block-7-8-x-1-7-8-in-1611862p.html#srp

The middle piece has the openings for the two hoses (the one that the router descends through) and the vaccum line. I just cut the top side of the vac one to fit my vac hose outside diameter. The two compressible vinyl duct lines hang from the top piece for about 4 rings (the metal spirals in the duct) and the bottom piece has bristles from a metal door sweet in a groove.

So it looks and works similarly to the one in the video. It does angle nicely over edges and it provides excellent suction. The vinyl duct is a bit stiff and I should probably weight it down and let it stretch out. It tends to recoil itself and draw back up whereas I would prefer it’s default position be fully extended.

Removing the shoe in my design is a treat as the two magnets hold it very firmly but allow it to be removed in 1s for bit changes etc. and it just snaps back on and the locating holes put it in the exact position.

I don’t have a photo of mine handy but will take one and post it when I get a chance. But I wanted to float the idea out there to the bright minds on the forum as I think this is a very interesting direction to go with a dust shoe design. Making it lighter than my concept and improving the attachment method are the principle issues at the moment. I could use a compression ring around the router like the CNC Swede example but I was hoping to avoid that complexity of that (having to drill through end grain for the fitting) and make the entire thing on my machine.

I’ve also considered getting the steel plate the router mount is installed in to re-made with accessory holes or slots as an option to improve mounting possibilities, but that’s a larger project I would need to send out…

Curious what others think of this innovative design.

-Jeff

Th