Can someone direct me to where to begin and a sequence of the steps to learning CNC. I have my 30x48 Longmill set up seems to be working fine. I need to make a spoil board yet. I don’t have any bits I plan on using this for acrylic mostly to begin with. I prefer videos helps me a lot I believe. Thank You

@jkjfenlee Welcome to the group, Jeff.

I’m sure that there will be a lot of advice offered.

You can help by giving a bit more information.

For example:

-

Do you have any CAD/CAM software yet? If so, what is it? If not, do you have plans to buy a program or do you want to stick with free applications?

-

What are you using to “talk” to the Long Mill? That is, what OS are you running? Windows, Mac, Pi?

-

Do you plan to use gSender as your code sender or another application?

-

You say that you will work primarily in acrylic. What sort of projects do you anticipate doing? Will this be a business for you, or a hobby"

-

Peripherally, what do you have or plan to have for dust collection?

There are countless excellent Youtube videos that may be helpful. However, without knowing more about your intentions, it really is not possible to point you to relevant ones.

I am planning on using InkScape software. I dont know if that will talk to the Long Mill.

I am not sure what I need for it to talk. I am hoping free software will be good enough?

I have both Mac and PC, I bought a PC just for the long Mill.

I can use G sender if it is easy enough to use unless there is more user-friendly programs?

I would like to make the work with acrylic to be a small business.

I did buy the add on dust collector for a shop vac.

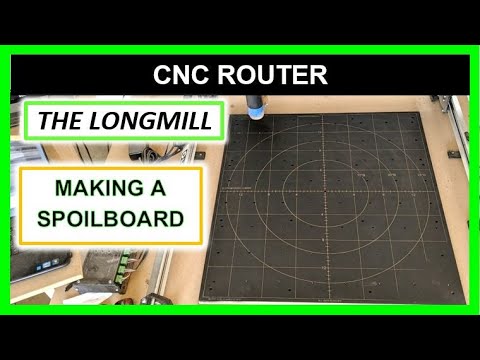

Here is a youtube of a spoil Board made by Garrett Fromme. You would have to modify it for a 30x48 but it gives you a place to start.

One of the things I did to learn was

- come here for information. Check out feeds and speed.

- I would decide what I wanted to make then google different videos, there are many on just about anything you could ever want to make.

- I believe that play is one of the best ways people learn, yes you will break a few bits but you will learn from those mistakes.

Really nice video. Is the something simpler. I am reluctant of removing parts of the Long Mill to cut this spoil board, and a little nervous. I am not going to do 2 side cutting. Can you suggest something simpler? I still haven’t done anything on the long mill yet besides putting the long mill together. I am very appreciative of help.

@jkjfenlee Hello Jeff, and welcome to the group! Here is an easy project to start off with.

Remember, that we were all at the same starting path as you were once. While scary, the LongMill is quite forgiving too.

No such thing as a dumb question. I have asked my fair share of doozies since I arrived about a year ago. Give this project a try!

Jake

Thanks Jake! I will give it a try I should have some bits by next week so I can begin. Ill let you know how it goes Thanks again!

Hello,

I believe I have the CAD understood and use Coral Draw. Question how do I take the file and do the CAM part of the process? I need to set up the bits speed and depth. I am going to cut out letter acrylic letters should not be too difficult. Guidance videos would be welcome. Thanks

I searched for how to do the CAM part of the process with CorelDRAW and I found this page. They mention a couple of CAM options for CorelDRAW. CamDRAW is a plugin for CorelDRAW but it cost $459. They also mention Easel and that is what I would recommend that you try. It has a free trial for the Pro version and when the trial is done you get to keep using the regular version for free.

I don’t have experience with Easel but from what I have read it’s one of the simplest options to use. You would export your design from CorelDRAW as an SVG probably and then import that SVG into Easel and use Easel to make the tool paths.

I’m not sure how to make the tool paths in Easel but that should be easy to find out by watching some YouTube videos like this one.

After making the tool paths you can then use Easel to send the G-Code to the LongMill or you could use gSender which is also free.

Hope this helps and welcome to the group Jeff.

Thank You I will try it this weekend. I had tried the Vcarve trial version and that was limited for bits that could use because it is a trial version I believe. I will try Easel as you mentioned. A big thank you for looking up the links. I also will need to learn how to change out bits in the carving mode. I feel things are coming together but just have to learn each stage and link them together. The CAM process I need to get a grasp on and then I should be able to begin.

Wanted to touch on changing out bits during carving. I find it easiest to set up different tool paths for each stage/bit of the project. It is possible to do tool changes in one G-Code file but after almost 2 years of LongMill usage I still don’t really see an advantage to combing multiple tools into one G-Code file unless you have some kind of automatic tool changer.

Just my opinion but it works and follows the KiSS principle.

EDIT: Forgot to add that most of the time I will use the same start point for all the bits so you only have to set Z zero for the new bit. If the XY start point is the same there is no reason to probe X or Y again.

Thank you for the information.

Hands down, the best software I ever purchased for CNC was Vectric. I don’t work there, I don’t get any kind of kickback, I have been using CAD software for way too many years (1980’s). Vectric is an all in one solution with the included necessary post processor. I would step away from other software and learn Vectric!!!

And the people that make the Longmill MK2 are also a reseller for Vectric software. Good fit!!!

Rick, I see they have a few to choose from. Does the Pro version an all in one version?

Do you mean VCarve Pro? If you purchase VCarve Pro you will have almost all the features that Vectric offers. You’ll only be missing the 3D modeling/sculpting which is only in Aspire for $2000 US. That’s some major sticker shock for me so I do my 3D modeling/sculpting in other software like Blender for free.

In case you don’t know, Vectric has a good upgrade system where if you buy say VCarve Desktop and decide you need VCarve Pro you can upgrade for the price difference.

Pro is the best start with no size limits

All in one and lots of video help. I’m still learning too on the Aspire 3d side

As @_Michael stated, the upgrade system is awesome if you want to get in to 3D.

I am also new to the CNC world. I have found Garratt from IDC Woodcraft to be an excellent resource on Youtube Does a great job of explaining all aspects of s/w, hardware, bits etc

Welcome @Stangard to the forum. I’ve been absent for the last month or so, just felt like looking and seen nobody greeted you properly. Good folks, excellent advice. @IDCWoodcraft is an excellent resource for new CNC creators. This forum is a wealth of knowledge too. Again, welcome Stan!

Jake