Hey Everyone, I’ve been lurking around the last few weeks after I got the goofy idea in my brain I needed one of these machines. Having looked at a few of the other options in the market (Shapeoko, Onefinity primarily) I feel like this is the most likely solution. But there’s a few things I’m having issues getting some clarity on and hoping those with some experience can help fill in the gaps. For reference I’m eyeballing this as an even mix of business/personal purchase, looking to hopefully make a bit of side income, maybe pay for a vacation/year or buy a bit more freedom from the regular day job as it were. Use cases would be primarily wood, custom signs, some relief carvings and such, could definitely see me experimenting with acrylic a bit with light up signs and maybe a bit of dabbling with aluminum/brass if I find a particularly catching project.

-

Total consideration of costs. Please note this is all in Canadian dollars. The longmill beginners kit at 30x48" is currently the winner, I feel as though the opportunity to potentially do some longer projects is worth extra upfront cost. With the beginners kit, shipping, some T tracks, a few hundred for lumber to build a table, a Home Depot 5 gallon bucket dust collector to attach to my shop vac along with a small handful of tools (calibers, squares, etc) and a vortex, I feel like I’m hitting 4.5-5k CDN. Do you feel as though that’s reasonably accurate value? Am I missing anything obvious? Eventually I feel like a used windows laptop and a copy of vectric pro will be purchased but will try and hold off on that until necessary.

-

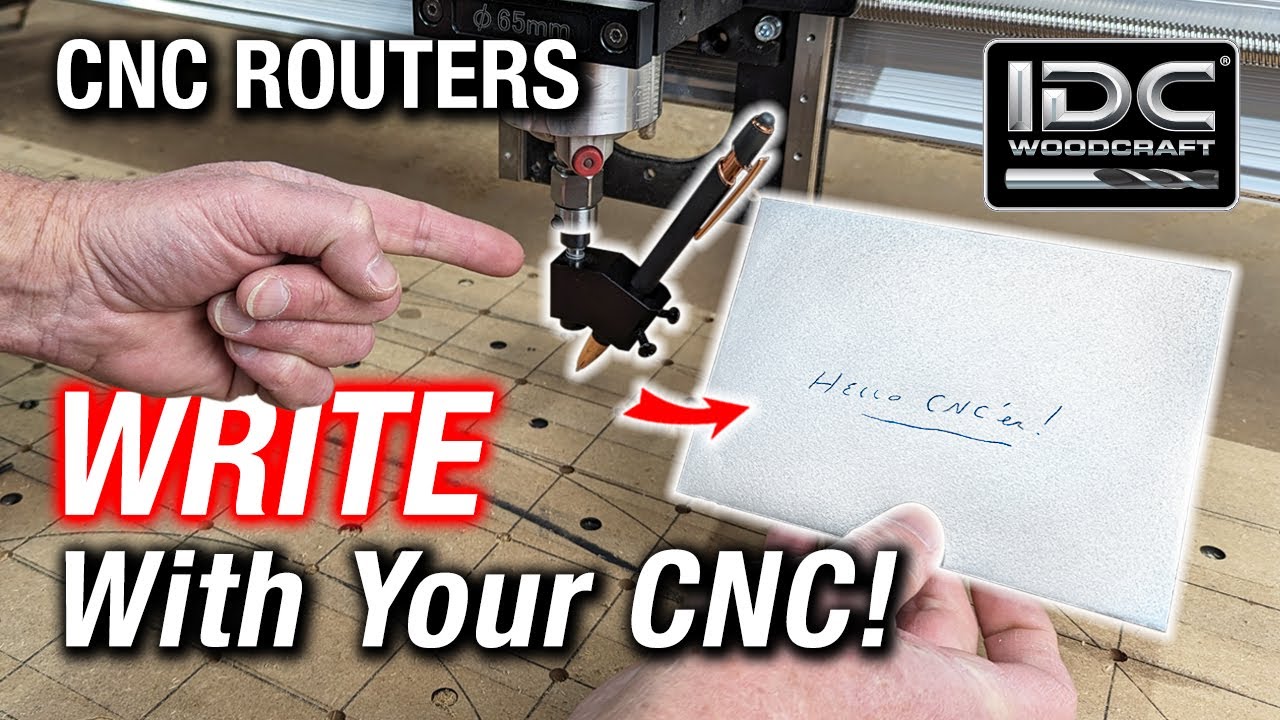

trying to find information regarding tooling options for the Long-mill. Just want to confirm that I can outfit a laser, diamond drag, or etcher if I decide to expand my capabilities? If I wish to get into laser etching things, Sienci no longer offers a laser by the looks of things, just accessories. Which lasers are readily available is everyone using?

-

Table designs: I found the post detailing a few of the amazing designed built by the community members but I didn’t see much in the way of links to build plans. Wondering if there was any fan favourite options for pre made table choices or easily modifiable options that can also break down easily for transport in the future (Mill would be setup in the basement, breaking down into smaller manageable pieces and ability to be hauled up/down stairs is critical). I can definitely fab something up but not having access to a jointer or planer I will have to take some extra time and consideration for the table (and lets be honest, the table is just extra ‘work’ before you get to the fun part!).

-

Training costs, by this I mostly mean lumber and bits. Learning is a never ending process but at the beginning the muck ups will be far more frequent. What was your favourite learning material? I don’t have a large supply of cut offs and such I can pull from so my mistakes will be paid for upfront unfortunately lol. I suspect the goldi locks of cheap, easy and quick, doesn’t apply and it’s a pick 2 situation here I’m guessing. Project boards from big box stores or construction grade lumber surfaced before hand as I play with settings the way to go?

I know this was a lot but any guidance would be appreciated as it’s a fairly sizeable jump into a big unknown (for me). Thanks again!

![How To Engrave Glass On a CNC Router [With A Drag Bit], Glass Etching](https://img.youtube.com/vi/TvmUO3Cvxmk/hqdefault.jpg)